Core functions and technical introduction

Release time:

2023-02-09

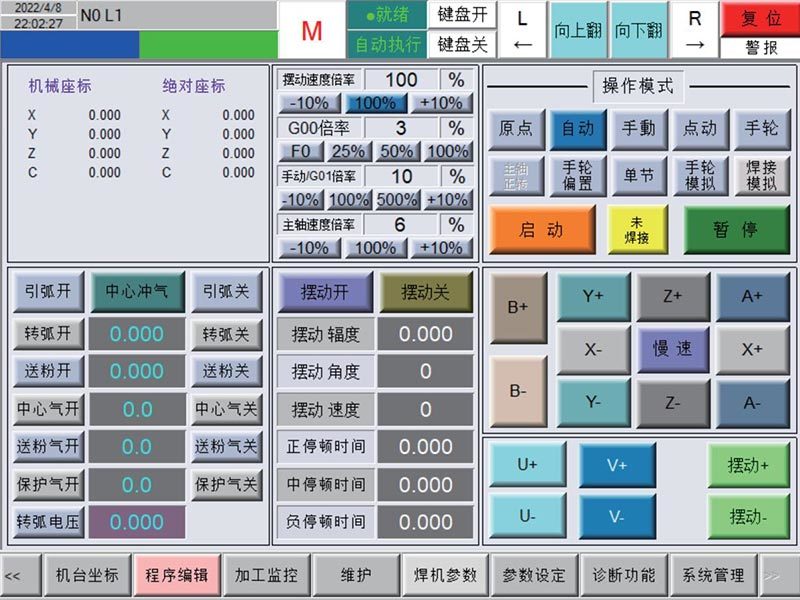

1. The control system adopts mature CNC in the market, with good equipment stability, multi-axis linkage and high trajectory flexibility. Special secondary development is carried out for the welding process, the operation and programming are simple and convenient, and the problem of unstable welding line speed caused by the rotation of the welding workpiece is solved. CNC unified management of all controlled objects, high integration and good coordination; Remote control can be carried out through special protocols and communication functions such as MODBUS/TCP.

1. The control system adopts mature CNC in the market, with good equipment stability, multi-axis linkage and high trajectory flexibility. Special secondary development is carried out for the welding process, the operation and programming are simple and convenient, and the problem of unstable welding line speed caused by the rotation of the welding workpiece is solved. CNC unified management of all controlled objects, high integration and good coordination; Remote control can be carried out through special protocols and communication functions such as MODBUS/TCP.

2. The welding machine and welding torch parts can be selected according to the characteristics of the customer's product process to adapt to the welding of different workpiece types and requirements such as excircles and inner holes. The welding current can reach up to 250A. After decades of market verification, it has good stability and durability, and can meet the requirements of iron-based, nickel-based and cobalt-based alloy powder spray welding.

3. The gas (central gas, powder gas and protective gas) is controlled by an electronically controlled flowmeter. The gas flow can be automatically adjusted in real time according to different current and powder usage during welding to ensure that the welding process is in the best state.

4. Precision powder feeder is a key component independently developed by our company and has independent intellectual property rights. It adopts stepping motor control, digital adjustment, high powder feeding precision, unique airflow structure, and long and stable powder transmission distance. With transparent observation window, the working condition and powder allowance are clearly visible and extremely intuitive. Various unloading methods (powder change at unloading port, powder change at pouring out, powder change at motor sending out), it is easy to use. A special structure is adopted to improve the particle size uniformity of the outflow powder. Double powder feeder can be used for uniform mixing of two different powders. You can choose non-stop powder adding option, powder residual alarm and heat preservation system; You can also choose a powder weighing system to know the powder status in real time.

| Project | Parameters |

| Powder delivery (g/min) | 0-60 |

| Powder feeding error | ≤ 2% |

| Loading capacity (kg) | 8,12 |

| Powder specification (mesh) | 80-320 |

| Powder feeding air flow (l/min) | 1-5 (intelligent adjustment) |

| Powder feeding gas pressure (MPa) | 0.3-0.4 |

| Powder feeding type | Roller stepping |

5. The automatic arc tracking system (AVC) is especially suitable for welding large workpieces, inconvenient installation and adjustment, and uneven welding surfaces. When the system is used for welding, the height of the welding torch will automatically adjust its position within a certain range to adapt to the change of the surface of the workpiece, so that the distance between the welded workpiece and the welding torch will remain basically unchanged and the welding quality will be improved. The tracking adjustment range is 10mm, the tracking voltage range is 5-50V, and the voltage accuracy is ± 0.1V.

6. Welding position tracking is mainly aimed at the error of the position of the workpiece (such as long blade), and the welding position is not accurate. The component adjusts the welding position in real time by detecting the boundary characteristics of the workpiece.

7. The two-axis intelligent swing device can automatically track the welding movement track and automatically swing in accordance with the track method to meet the linear, serrated, and oblique circular welding movement methods. The swing movement axis can be combined with the welding movement axis, and the structure is simple; The speed and other parameters can be adjusted during operation, which is convenient to use.

Swing amplitude 80mm

Swing angle 0~360 °

Speed 200-1500 mm/min

Can freely set the left, middle and right pause

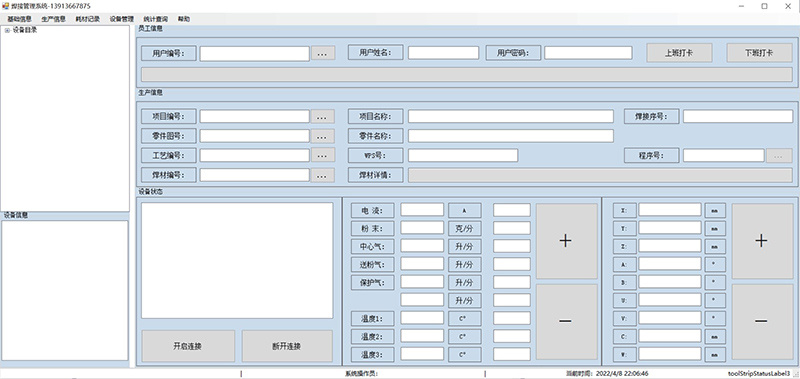

8. Welding management system (WMS) can be very convenient to check, adjust the welding parameters, edit the document. The welding current, voltage, temperature, etc. can be displayed in a curve graph to provide you with the required report files. The welding video is provided through a special camera, the quality is tracked in real time, and the welding parameters and welding position are fine-tuned remotely. Remote diagnosis, maintenance and software update of equipment can also be carried out through customized option function packages.

Related News

Nantong Xinding Automation Technology Co., Ltd.

Address: 20 Zhongtian Road, Nantong City

Telephone: 86-13913667875

E-mail: cszhaoweihua@126.com

Scan QR Code

Copyright©2023 Nantong Xinding Automation Technology Co., Ltd.