Laser cladding equipment

Laser cladding equipment

Mainly engaged in plasma welding and laser cladding and other automated welding equipment research and development, production and sales. The products are deep into many fields, such as aerospace and military industry, automobile, steel, cutting tools, molds, nuclear power, petrochemical, coal mining, cement, electric power and other industries.

Classification:

Key words:

Machine Tool | Laser Cladding | Plasma Surfacing | Welding Equipment

Product Consulting:

Details Introduction

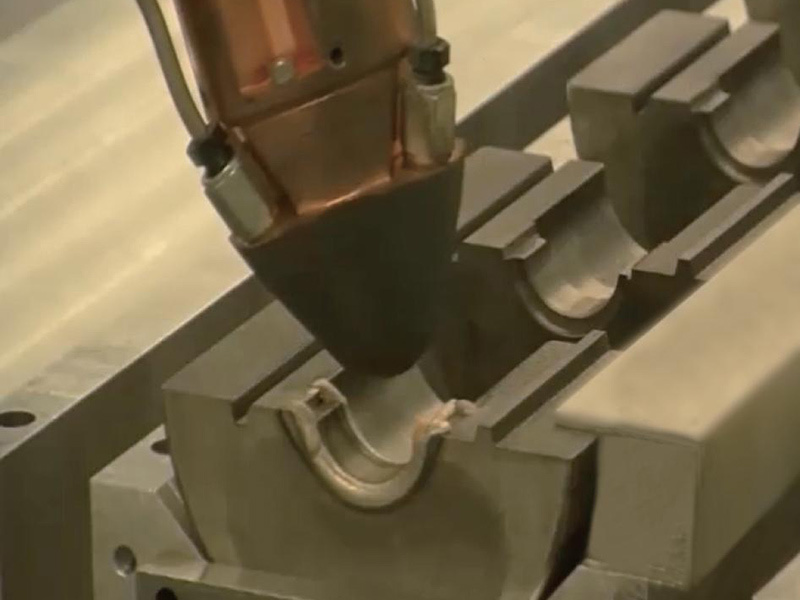

Laser cladding is a new type of surface modification technology, which belongs to the field of additive manufacturing. A selected coating material is placed on the surface of the coated substrate, and a thin layer on the surface of the substrate is simultaneously melted and rapidly solidified by laser irradiation to form a surface coating with extremely low dilution and metallurgical bonding with the substrate material, which can form a high-performance alloy layer on the surface of ordinary metals, thus reducing costs and improving the heat resistance of the surface of parts, corrosion resistance, high temperature resistance and other comprehensive performance.

Laser cladding technology has been widely used in aerospace, petrochemical, military, medical and renewable manufacturing and other fields, saving a lot of resources and manufacturing costs.

The laser cladding energy control is concentrated, the heat input is small, the deformation of the workpiece is small, the cladding layer and the surface of the workpiece are metallurgically bonded, and the bonding strength is high.

The laser cladding equipment produced by our company can choose customized machine tools and robots as moving parts. The robots can choose famous brands at home and abroad such as An Chuan, KUKA, ABB, FANUC, Eston, etc. The robot system can be customized according to customer products to meet different needs. The cladding head adopts multi-channel coaxial powder feeding or annular powder feeding. Domestic 2-6kW fiber laser or German Laserline semiconductor laser can be selected.

The impact of alloying on the organization and properties of laser melting coating is wear resistance and hardness. The organization and properties of laser clad nickel-based self-melting alloy coatings are inextricably linked to their alloying element content, and their hardness and wear resistance increase with the increase in the content of alloying elements such as chromium, boron and carbon.

Laser cladding is a new type of surface modification technology that uses a laser beam to heat the surface of the cladding material and the substrate, so that the desired special material is fusion welded to the surface of the workpiece. Compared with the commonly used cladding and plasma spray welding (coating) and other technologies, laser cladding technology has a series of outstanding features: the cladding layer organization is fine, dense, cladding hardness is higher, corrosion resistance, wear resistance is better; cladding and substrate for the metallurgical bonding; the cladding layer has a low dilution rate (only 5% to 8%), the cladding can be a thinner to achieve the desired performance requirements; the power density of the laser beam, the heating temperature is high, the choice of cladding material is wider; the choice of cladding material is wider; the choice of cladding material is wider; the choice of cladding materials is wider; the choice of cladding materials is wider; the choice of cladding materials is wider. Wider selection range of cladding materials; small heat-affected zone, less deformation of the workpiece; stable quality of the cladding, easy to realize automated production.

Product recommend

More needs, please contact

We will contact you within one working day. Please pay attention to your email.

Nantong Xinding Automation Technology Co., Ltd.

Address: 20 Zhongtian Road, Nantong City

Telephone: 86-13913667875

E-mail: cszhaoweihua@126.com

Scan QR Code

Copyright©2023 Nantong Xinding Automation Technology Co., Ltd.