Introduction of plasma surfacing principle and process

Release time:

2023-02-09

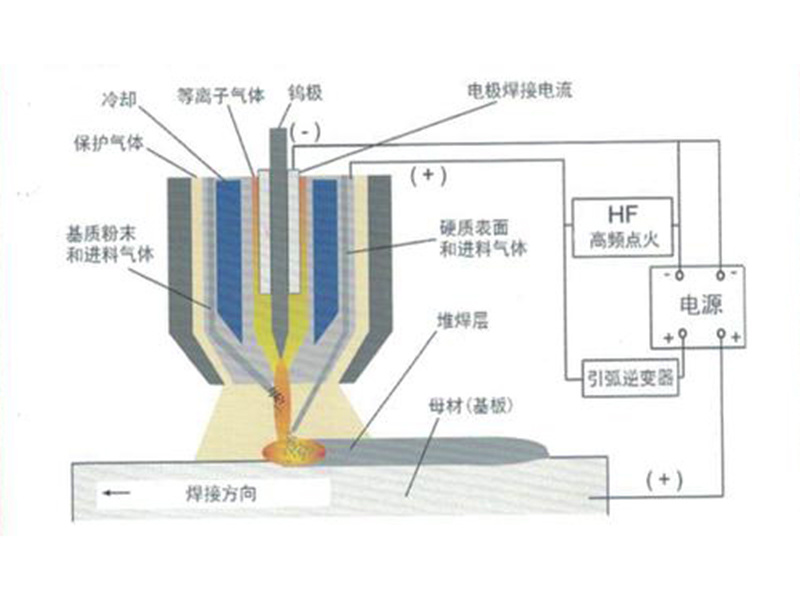

Plasma welding is between the electrode and the workpiece, through the special compression mechanism of the welding torch, the formation of a stable plasma compression arc as a heat source, the resulting high temperature alloy powder and the surface of the substrate quickly heated and melted, mixed, diffusion, solidification, forming a layer of high-performance alloy layer, so that the surface of the parts with better high temperature resistance, corrosion resistance and wear resistance of the welding process, it is a new surface cladding modification technology with high quality, high efficiency and low cost.

Plasma welding is between the electrode and the workpiece, through the special compression mechanism of the welding torch, the formation of a stable plasma compression arc as a heat source, the resulting high temperature alloy powder and the surface of the substrate quickly heated and melted, mixed, diffusion, solidification, forming a layer of high-performance alloy layer, so that the surface of the parts with better high temperature resistance, corrosion resistance and wear resistance of the welding process, it is a new surface cladding modification technology with high quality, high efficiency and low cost.

Plasma gas is generally 99.99% of high-purity argon, with good ionization capacity and arc stabilization effect, the protective gas is generally high-purity argon, but also according to the different materials of argon, hydrogen and helium and other different ratios.

Related News

Nantong Xinding Automation Technology Co., Ltd.

Address: 20 Zhongtian Road, Nantong City

Telephone: 86-13913667875

E-mail: cszhaoweihua@126.com

Scan QR Code

Copyright©2023 Nantong Xinding Automation Technology Co., Ltd.